Refrigerants – What Are They & How Do They Work?

Refrigerants are the lifeblood of cooling systems, making air conditioning, refrigeration, and heat pumps possible.

These specialized fluids absorb and release heat as they cycle through a system, enabling temperature control in everything from home AC units to industrial chillers.

The Early Days: Natural Refrigerants (1800’s – Early 1900’s)

🔹 Refrigerants Used: Ammonia (NH₃), Carbon Dioxide (CO₂), Sulfur Dioxide (SO₂)

🔹 Why They Were Used: Naturally available, effective cooling properties

🔹 Challenges: Toxicity (ammonia, SO₂), high pressure (CO₂)

Before synthetic refrigerants took over, the world relied on naturally occurring substances to achieve cooling. In the 19th and early 20th centuries, refrigeration was a revolutionary concept, and scientists experimented with ammonia (NH₃), carbon dioxide (CO₂), and sulfur dioxide (SO₂) as early cooling agents.

These refrigerants were highly effective, but they came with challenges—ammonia was toxic, CO₂ required high pressures, and sulfur dioxide was corrosive. Despite the risks, these substances powered the first commercial refrigeration systems, making ice production, food preservation, and even air conditioning possible.

However, as industries grew and refrigeration expanded into homes, the demand for safer, more efficient alternatives led to the invention of synthetic refrigerants. Little did they know, this shift would eventually trigger one of the biggest environmental crises of the 20th century.

The Transition To CFCs & HCFCs (1930s – 1990s)

Chlorofluorocarbons

&

Hydrochlorofluorocarbons

🔹 Refrigerants Introduced: R-12, R-22 (Freon)

🔹 Why They Were Popular: Non-toxic, non-flammable, efficient

🔹 Environmental Downside: Ozone depletion (CFCs & HCFCs destroy the ozone layer)

🔹 Regulatory Action: Montreal Protocol (1987) began the phaseout of ozone-depleting substances

🌍 The Montreal Protocol: The Treaty That Saved the Ozone Layer & Transformed Refrigerants

The Transition To HFCs (1990s – 2020s)

Hydrofluorocarbons

🔹 Refrigerants Introduced: R-134a, R-410A, R-404A

🔹 Why They Were Used: No ozone depletion, better performance than older refrigerants

🔹 New Problem: High Global Warming Potential (GWP), contributing to climate change

With the phaseout of CFCs and HCFCs following the Montreal Protocol, the world needed a new class of refrigerants that could keep cooling systems running without depleting the ozone layer. This led to the rise of hydrofluorocarbons (HFCs), such as R-134a, R-410A, and R-404A. Unlike their predecessors, HFCs contained no chlorine, making them ozone-friendly, which was a major victory for the environment.

However, while HFCs didn’t destroy the ozone, they introduced a new environmental concern: global warming. HFCs have a high Global Warming Potential (GWP)—some are thousands of times more potent than CO₂ in trapping heat in the atmosphere. For example, R-404A has a GWP of over 3,900, meaning it traps 3,900 times more heat than the same amount of CO₂. As HFCs became the global standard in air conditioning, refrigeration, and automotive cooling, their contribution to climate change became undeniable.

By the early 2000s, scientists and governments recognized that HFCs could not be the long-term solution. This led to new global agreements, like the Kigali Amendment (2016), which set the stage for phasing down HFCs in favor of low-GWP alternatives such as HFOs, R-32, and natural refrigerants.

The Rise of Low-GWP Refrigerants (Present & Future)

🔹 Predictions: Natural refrigerants making a comeback, more energy-efficient HVAC systems

🔹 Regulatory Changes: More global bans on HFCs, new technologies like solid-state cooling

🔹 How This Affects You: Homeowners, HVAC techs, and business owners need to adapt

As the world shifts toward more sustainable and energy-efficient cooling solutions, the future of refrigerants is undergoing a major transformation. With stricter environmental regulations, increasing global temperatures, and advancements in HVAC technology, the industry is moving toward low-GWP alternatives, natural refrigerants, and entirely new cooling methods.

🌍 The Push for Ultra-Low-GWP Refrigerants

Governments and industry leaders are rapidly phasing down high-GWP refrigerants, enforcing bans and incentives to adopt more climate-friendly alternatives. The Kigali Amendment to the Montreal Protocol is leading the charge, aiming to cut HFC emissions by 85% by 2047, which could prevent up to 0.5°C of global warming.

🚀 Emerging Refrigerants & Their Advantages:

• R-32 – Already replacing R-410A in many residential ACs, with a GWP three times lower.

• HFOs (Hydrofluoroolefins) like R-1234yf – Used in cars and HVAC systems, breaking down much faster in the atmosphere.

• Natural Refrigerants (CO₂, Ammonia, Propane) – Nearly zero-GWP and making a strong comeback in commercial and industrial cooling.

• A2L Refrigerants – A new category of mildly flammable, low-GWP refrigerants designed for modern HVAC systems.

Montreal Protocol:

Established in 1987, the Montreal Protocol was designed to phase out substances that deplete the ozone layer, notably chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). The protocol’s success is evident in the ongoing recovery of the ozone layer, which is projected to return to 1980 levels by around 2040 for most of the world.

Kigali Amendment:

Recognizing the environmental impact of hydrofluorocarbons (HFCs), which, while not ozone-depleting, possess high global warming potentials (GWPs), the Kigali Amendment was adopted in 2016. This amendment mandates a global phase-down of HFC production and consumption by over 80% over the next 30 years. If fully implemented, it could prevent up to 0.5°C of global warming by the end of this century.

Impact on Refrigerant Phaseouts:

The combined efforts of the Montreal Protocol and the Kigali Amendment have led to significant shifts in the HVAC industry:

• Transition to Low-GWP Refrigerants: There’s an accelerated move towards refrigerants with lower GWPs, such as hydrofluoroolefins (HFOs) and natural refrigerants like ammonia (R-717) and carbon dioxide (R-744).

• Regulatory Compliance: Countries are implementing policies to meet the phase-down schedules, influencing the availability and usage of certain refrigerants in the market.

• Technological Innovations: The industry is innovating to develop equipment compatible with alternative refrigerants, focusing on energy efficiency and safety.

Safety Handling

Key Safety Protocols:

1. Personal Protective Equipment (PPE):

• Always wear appropriate PPE, including gloves, safety goggles, and protective clothing, to prevent skin and eye contact with refrigerants.

2. Proper Ventilation:

• Ensure work areas are well-ventilated to prevent the accumulation of refrigerant gases, which can lead to asphyxiation or create flammable environments.

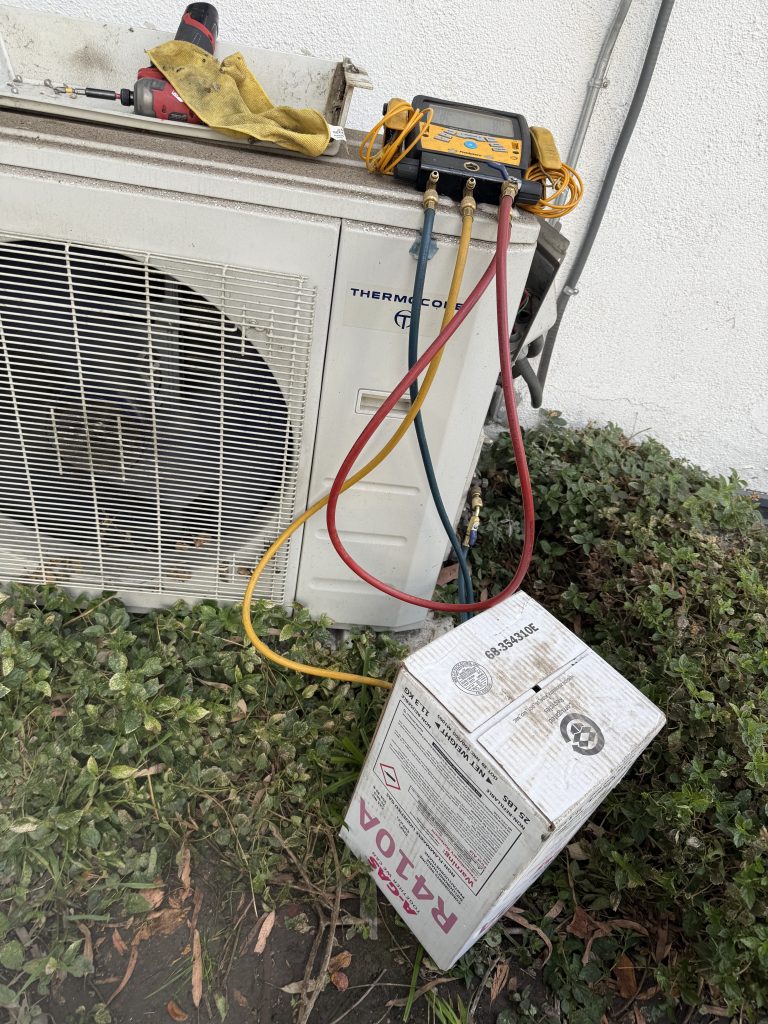

3. Leak Detection and Repair:

• Regularly inspect systems for leaks using appropriate detection methods. Promptly repair any identified leaks to prevent refrigerant release into the environment.

4. Safe Storage and Transportation:

• Store refrigerant cylinders upright in a cool, dry place away from direct sunlight and sources of ignition. Secure cylinders during transportation to prevent movement and potential damage.

5. Handling Flammable Refrigerants:

• For flammable refrigerants, eliminate potential ignition sources in the work area. Use non-sparking tools and ensure that the quantity of flammable refrigerant per device does not exceed recommended limits.

6. Training and Certification:

• Technicians should undergo proper training and obtain necessary certifications, such as the EPA’s Section 608 certification in the U.S., to ensure they are qualified to handle refrigerants safely.

7. Emergency Procedures:

• Establish and familiarize yourself with emergency procedures, including evacuation plans and first aid measures, in case of accidental refrigerant release or exposure.